打破瓶颈,重塑效率

Tiger Team 如何让流程焕然一新?

在生产高功率球场专用照明设备的产线上,时间和品质一样不可妥协。一旦正式开线,所有参数就会被锁定,自动化流程精密运作,几乎没有「回头路」可走。

那天,是我们正式启动生产的第一天。

产线参数才刚进系统没几个小时,客户就打来了。

「真的很不好意思,」对方语气诚恳,「业主临时更改了灯具的性能需求。我们知道你们的产线已经启动了,如果会造成损失,我们可以按照合约负担……但如果你们愿意协助,我们会非常感激。」

我们请他们先稍安勿躁。给我们一个晚上,我们会全力以赴。

当天晚上,一支临时集结的 Tiger Team 在厂房会合。团队里有年轻的工程师,也有经验丰富的产线老前辈——詹组长。他从 1989 年就投身照明行业,是公司最资深的一线技术专家之一。

「这个情况……其实我二十年前就想过一个做法,」詹组长慢慢说,「一直没有用上。」

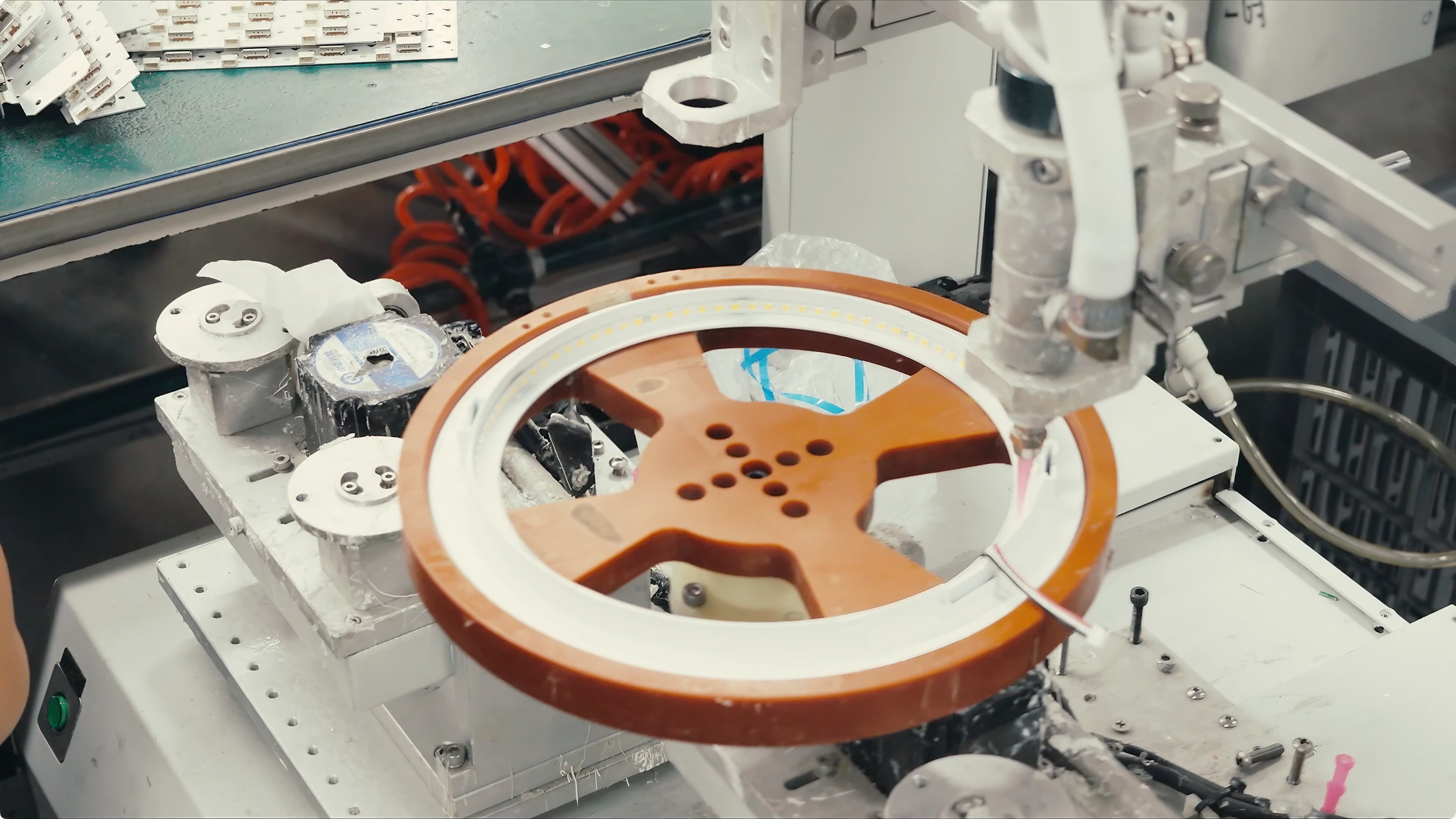

他在白板上画出一个圆形的旋转送料盘:安装在主线上需要插入工序的位置,把产品暂时送进旁边的支线加工,完成后再送回主流程继续走。只要送料盘的转速控制得好,整体节奏不会被打乱。

听完他解释,年轻工程师立刻打开 CAD 软体开始建模,参数迅速被重新运算。詹组长站在一旁,一边看着模拟图,一边点头确认。

整个晚上,大家全神贯注、不眠不休。

天亮时,新的插入模组已经安装完毕并开始运作。

产品如期交货,流程无缝衔接。

客户事后说:「你们的产线看起来就像一场编排精准的舞蹈——安静、顺畅、令人佩服。」

从那之后,我们跟这位建商的合作从未中断。

—

这不只是一次技术调整,更是经验与行动力交会的火花,是一张尘封二十年的手稿,终于在关键时刻变成现实。

Some production lines are built for speed. Others for precision. Ours, in this case, was designed for finality.

When you're manufacturing high-power LED fixtures for professional stadiums, the process is tightly engineered — not just for quality, but for timing. Once the order hits the line, it runs like clockwork. Parameters are locked. Materials move. Automation takes over. Changing anything after launch typically means starting from scratch.

This time, production had barely begun.

On day one — just hours after we activated the line — the contractor called.

The tone was apologetic but urgent. “The stadium owner made a last-minute change. It affects the fixture’s performance spec. We know the line is already running — and we’re fully prepared to absorb any production losses under contract. But… if there’s any way you could help, we’d be incredibly grateful.”

We told them to hold off on decisions. Give us one night. We’d do everything we could.

That evening, our Tiger Team assembled — systems engineers, automation leads, and an old hand named Mr. Zhan. He entered the lighting industry in 1989. Thirty-five years in the trenches. A builder’s mind, shaped by time.

As the team debated options, Zhan remained quiet, then finally said, “There is one idea I once sketched… a long time ago.”

He recalled a concept he had first imagined during a factory renovation in the early 2000s: a rotary buffer disk inserted into a fixed-flow production line. “You place a rotating disk right at the point where the new process needs to happen,” he explained. “It spins clockwise to detour units into a temporary sub-line, then rotates again to return them to the main flow.”

The beauty? You don’t stop the entire line. You just open a side door.

The younger engineers lit up. CAD software opened. Simulations began. Zhan reviewed the timing calculations. “As long as the disk speed matches the main flow rate,” he said, “you won’t lose a second.”

They got to work.

Through the night, they prototyped, fabricated, and installed a modular branch — not from scratch, but docked directly onto the existing infrastructure. By dawn, the system was running. The updated components were inserted mid-line and rejoined the main route like nothing had changed.

But everything had.

The lights shipped on time. The contractor later told us, “It felt like watching choreography — smooth, invisible, brilliant.” They’ve trusted us ever since.